Maximize Warehouse Efficiency & Safety: The Power of Striping

Every square foot in your warehouse is valuable real estate. An inefficient layout not only wastes space but also poses significant safety risks, potentially hindering productivity and increasing operational costs. According to the Bureau of Labor Statistics (BLS), the rate of injuries and illnesses for the transportation and warehousing sector was 4.0 per 100 full-time workers in 2021. This is significantly higher than the national average across all industries (2.3 per 100 full-time workers). Strategic warehouse striping and floor markings can address these challenges by optimizing space utilization, enhancing safety, and boosting overall efficiency. Let’s explore how striping can transform your warehouse operations with these warehouse striping tips.

Beyond the Lines: How Striping Optimizes Your Warehouse

Space Optimization

Clear Designation:

A clearly marked warehouse floor is crucial for both safety and efficiency. As noted in a guide by Occupational Health & Safety (Guide for an Effective Warehouse Layout Design to Reduce the Risk of Accidents and Boost Productivity), separating pedestrian and vehicle traffic with designated lanes is essential. This reduces confusion and ensures a smooth workflow throughout the warehouse. Clear signage for easy navigation and well-designed pathways further enhance safety and efficiency. Designated areas for storage, receiving, and shipping, as well as good overall visibility, can prevent bottlenecks and ensure goods are processed swiftly and correctly.

Traffic Flow Management:

Designating one-way aisles, pedestrian walkways, and specific areas for forklifts ensures smooth traffic flow and minimizes congestion, preventing accidents and delays. This organization helps streamline operations and keeps your warehouse running efficiently. Implementing marked paths for forklifts can drastically reduce the chances of collisions and improve overall safety.

Improved Usage:

Optimized storage layouts with designated zones for specific inventory types eliminate wasted space. By using vertical space with proper markings, you can maximize storage capacity, making the most out of your warehouse’s square footage. For example, vertical striping can help guide the proper stacking of pallets, ensuring safe and efficient use of space.

Enhanced Safety

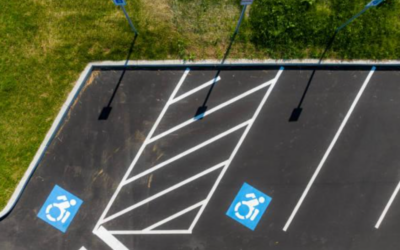

Clear Designation of Safety Zones:

Clearly marking pedestrian walkways, emergency exits, and areas for hazardous materials with high-visibility striping promotes safety awareness and helps prevent accidents. These markings ensure that employees are aware of safe paths and danger zones at all times. High-visibility paint, combined with reflective materials, can further enhance safety in low-light conditions.

Improved Traffic Flow & Forklift Safety:

Well-defined traffic lanes and designated loading zones with clear markings minimize forklift collisions and accidents. This alignment with OSHA’s traffic flow and powered industrial truck regulations ensures that your warehouse meets safety standards and reduces the risk of costly incidents. Regular maintenance of these markings is crucial to ensure they remain visible and effective.

Visual Cues for Worker Awareness:

Clear markings act as visual cues for workers, reminding them of designated work areas, forklift traffic patterns, and safety protocols. This promotes adherence to safety regulations and reduces the risk of accidents, fostering a safer work environment. Consider using different colors for different zones to enhance visual recognition and adherence to safety protocols.

Increased Productivity

Streamlined Workflow:

Efficient traffic flow and organized storage layouts with clear markings enable faster product movement and more efficient picking/packing processes. This reduces time spent searching for items and improves overall workflow, allowing for quicker fulfillment of orders. Clear markings offer numerous benefits for warehouse efficiency, including:

- Directing pedestrian and vehicle traffic: This reduces congestion and ensures everyone knows where to walk or drive.

- Identifying designated areas: Clearly marked zones for storage, picking, packing, and shipping can streamline workflows.

- Improving product visibility: Clear markings can highlight frequently picked items or fragile goods, making them easier to locate.

Reduced Errors:

Clear markings and designated areas minimize confusion for workers, leading to fewer picking and order fulfillment errors. Improved accuracy in these tasks enhances customer satisfaction and reduces the costs associated with correcting mistakes. For instance, color-coded zones for different product categories can significantly reduce picking errors.

Improved Morale:

A well-organized and safe work environment fosters a sense of order and reduces stress for workers. This can lead to improved morale and potentially higher productivity, as employees feel more confident and comfortable in their workspace. Happy employees are often more productive, leading to better overall performance for your warehouse operations.

Conclusion

Warehouse striping is a strategic tool that can enhance efficiency, safety, and productivity in your operations. By clearly marking designated areas, managing traffic flow, and ensuring safety zones are visible, you can create a more organized and efficient warehouse. Investing in professional striping services can transform your warehouse, making it a safer and more productive space for your employees.

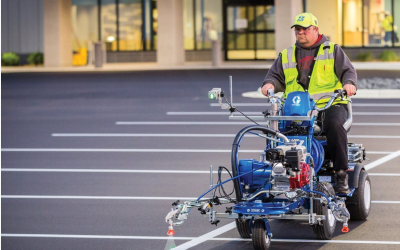

Ready to Transform Your Warehouse?

At Striping Done Right, we bring years of experience and a commitment to quality. Our tailored striping solutions improve safety, ensure OSHA compliance, and provide long-lasting results, saving you money and time.

Ready to transform your warehouse? Contact us today for a free consultation. Discover how our customized striping services can enhance your operations and help you achieve your business goals. Reach out now and benefit from our limited-time offer.