Introduction

Maintaining a safe and organized warehouse is a top priority for any business. OSHA-compliant floor markings play a crucial role in achieving this goal, helping to guide traffic, designate areas, and prevent accidents. For warehouse managers in Chicago and the surrounding regions, understanding and implementing these guidelines is essential. In this comprehensive guide, we’ll explore the key aspects of OSHA-compliant floor markings, from regulations and best practices to practical tips for maintaining your markings. By the end of this post, you’ll be equipped with the knowledge to ensure your warehouse is both safe and compliant.

What are OSHA Regulations for Floor Markings?

OSHA has specific standards for floor markings that aim to enhance safety in the workplace. These regulations cover everything from the color and placement of markings to their width and durability. Familiarizing yourself with these requirements is the first step toward compliance. Key points include using consistent color codes and ensuring markings are visible and maintained.

Color Coding and Their Meanings

OSHA recommends specific colors for different purposes. For example, red is used for fire-related hazards, yellow for caution, and green for safety equipment. Understanding these color codes ensures that your markings are both functional and compliant. Other colors like blue, orange, and white are also used to indicate specific areas or hazards. This standardized approach helps employees quickly understand and react to potential dangers.

Benefits of Proper Floor Markings

Investing in proper floor markings offers several benefits. First and foremost, it enhances safety by reducing the risk of accidents and guiding employees and equipment operators. Additionally, well-defined markings improve workflow efficiency by clearly designating pathways and storage areas. Lastly, compliance with OSHA standards helps you avoid fines and legal issues. Proper markings can also boost employee morale, as a well-organized workspace is easier to navigate and work in.

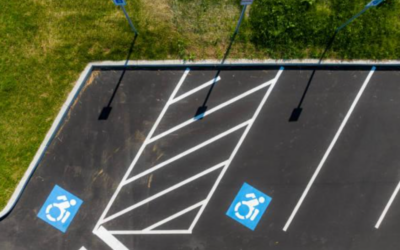

Types of Floor Markings and Their Uses

Color Codes and Their Meanings

OSHA recommends specific colors for different purposes. For example, red is used for fire-related hazards, yellow for caution, and green for safety equipment. Understanding these color codes ensures that your markings are both functional and compliant.

Types of Materials

When it comes to floor markings, you have a choice between paint and tape. Paint is durable and ideal for long-term applications, while tape is easier to apply and modify. Selecting the right material depends on your specific needs and the conditions of your warehouse. For example, if your warehouse experiences high traffic, durable epoxy paint might be the best choice. On the other hand, if you need flexibility and frequent updates, high-quality floor tape could be more practical.

Planning Your Floor Marking Layout

Effective floor markings start with a solid plan. Assess your warehouse layout, considering traffic flow, storage areas, and emergency exits. Involving your team in the planning process can provide valuable insights and ensure that the markings meet everyone’s needs. Detailed planning helps in visualizing the end result and identifying potential problem areas before they arise.

The Installation Process

Surface Preparation

Preparing the floor surface is crucial for ensuring that your markings adhere properly and last longer. This involves cleaning the floor thoroughly and repairing any damages. A clean, smooth surface provides the best foundation for durable floor markings. For warehouses in Chicago and surrounding areas, where dust and grime can accumulate quickly, regular cleaning routines are essential before applying any markings.

Measuring and Marking

Accurate measurements are essential for creating clear and consistent markings. Using guides and templates can help you achieve precision. Taking the time to measure and mark correctly will save you time and effort in the long run. Tools like laser distance measurers and chalk lines can assist in achieving perfect straight lines and angles.

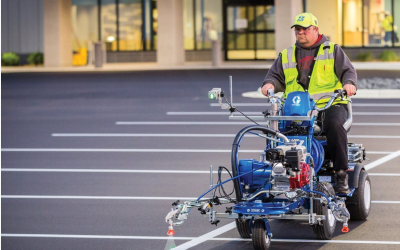

Applying the Markings

Whether you’re using paint or tape, applying the markings requires careful attention to detail. Ensure that the markings are straight, even, and visible. Allowing sufficient drying time for paint or ensuring tape is firmly adhered is crucial for durability. In high-traffic areas, consider using additional protective coatings to extend the life of your markings.

Maintenance and Inspection

Regular maintenance and inspections are vital for keeping your floor markings in top condition. This includes checking for wear and tear, reapplying faded markings, and ensuring that all markings remain clear and visible. Seasonal maintenance, such as addressing damage from winter conditions, can also help extend the life of your markings. For example, heavy machinery can cause significant wear on floor markings, necessitating more frequent touch-ups in those areas.

Training and Compliance

Training your employees on the significance of floor markings and how to follow them is essential for maintaining a safe workplace. Regular training sessions and updates on any changes to OSHA regulations will keep your team informed and compliant. Interactive training methods, such as quizzes and hands-on demonstrations, can improve understanding and retention of safety protocols.

Local Considerations for the Chicago Area

Warehouses in the Chicago and surround areas face unique challenges due to the region’s weather conditions and local regulations. Using high-quality, weather-resistant materials can help your markings withstand harsh winters and hot summers. Staying informed about any specific local requirements ensures your warehouse remains compliant. For instance, Chicago’s local safety standards might have additional requirements beyond OSHA’s guidelines, which must be incorporated into your floor marking plan.

Hiring a professional service like Striping Done Right, Inc. can make a significant difference in the quality and durability of your floor markings. Professionals have the expertise and equipment to deliver precise, long-lasting results. When selecting a service provider, look for one with experience, positive reviews, and a commitment to safety and compliance. Striping Done Right, Inc. not only ensures high standards but also provides tailored solutions for warehouses of all sizes in the Chicago area.

Conclusion

Proper floor markings are essential for maintaining a safe, organized, and OSHA-compliant warehouse. By understanding the regulations, planning your layout carefully, and using high-quality materials, you can create a safer environment for your employees. If you need assistance with your floor marking project, contact Striping Done Right, Inc. We’re here to help you achieve the best results for your warehouse.